We are a group of veterans with over 20 years

of experience in the Indian forging industry, specializing

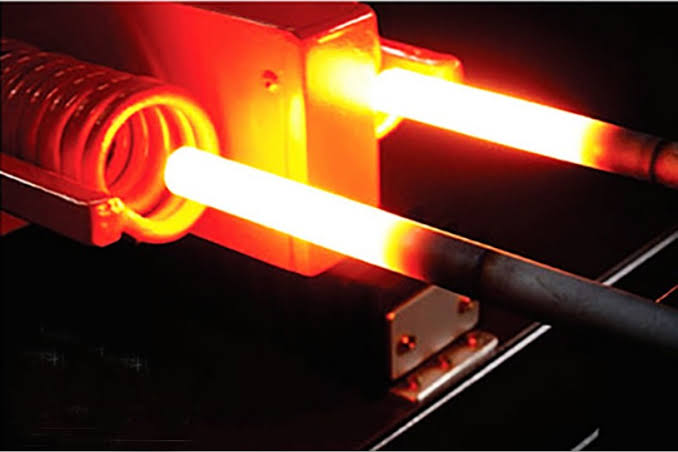

in billet heaters and handling systems. Our medium frequency induction billet and special heaters are

reliable, cost-effective, and easy to operate. They cater to various applications, including forging,

brazing, annealing, melting, and hardening.

Our machines are compatible with presses and hammers of different

sizes, ensuring they meet your

production needs efficiently. Our dedicated team of young engineers provides customized solutions and

maintains ready stock of spare parts at competitive prices. We have service engineers in Pune and Delhi

who can respond to calls within 24 hours across India.

In addition to induction heating equipment, we

manufacture fully and semi-automatic billet loaders. We

also offer power factor correction banks with reactors to maintain induction billet heaters' power

factors.

Please register us as your preferred vendor for all induction heating requirements. We look forward to

your inquiries and building a long-term relationship with you.

We look forward to building a long-term relationship with you.

| Item | Definition | Application Range | Frequency Selection | Power Selection | Suggested Model |

|---|---|---|---|---|---|

| Heat penetration | Heat the whole workpiece or partial workpiece to certain temperature | Heat distortion to Fastener, hardware tool, Auto Parts, tackles, pipes, etc | The bigger the diameter is, the lower the frequency is >35mm, 1-10Khz Φ16-40mm, 15-25Khz Φ4-16mm, 25-100Khz <Φ4mm, 100-700Khz |

The power selection depends on the workpiece diameter and production rate | >Φ35mm, MFS series Φ16-40mm, SWS series Φ4-16mm, CX series |

| Braze welding | Melting the brazing solder to joint two or more workpieces | Silver/copper/tin braze welding to diamond saw blade, hard alloy cutter, drills, pipes, electrodes | The smaller the heating area is, the higher the frequency is; the bigger the heating area is, the lower the frequency is | The power depends on the workpiece heating area and heating time | Smaller workpiece suggest to use CX series, big workpiece suggest to use SWS series |

| Heat treating | Heating the workpiece to certain temperature and then cooling them to reach different crystal phase, like hardening, tempering, annealing, normalizing | Heating treating to Shafts, plates, gears, hard alloys, stainless steels, gear wheels | The thinner the heating depth, the higher the frequency is; the thicker the heating depth is, the lower the frequency is | The power depends on the heating area and heating depth | Heating depth 0.5-1mm 100-250Khz 1-2mm 50-100Khz 2-3mm 15-35Khz >3mm 1-10Khz |

| Melting | Heating the metals to melting point and keep the temperature | Noble metals, non-ferrous metals, ferrous metals | The smaller the melting capacity is, the higher the frequency; the bigger the melting capacity is, the lower the frequency is | The power depends on the melting time and melting capacity | SWS-B series specialized melting machine |

Kailas Landge

9730867579

Flat.No A-506 Soham Apartment, Near Navbharat High School, Shivane Pune 411023

Servey No. 3, Khan Vasti, Near Scaleup Cricket Academy, Ram Nagar, Warje, Pune - 411052

9730867579, 9960436926